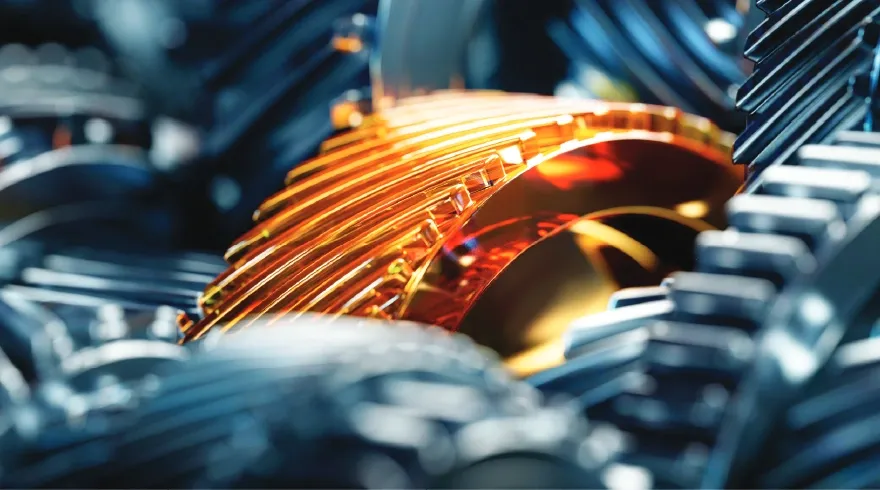

Hydraulic components, gears, and bearings in industrial machinery.

Resistant to swelling and degradation, particularly in glycol-free FRHF and synthetic ester formulations.

Protects steel and alloy components from wear, corrosion, and pitting under heavy loads.

Foundries, die‑casting, steel manufacturing, mining, forging, extrusion, tunnel boring, quarrying, die-casting industry

High‑speed spindle lubrication and also Lubrication of other precision machine parts and bearings

High‑speed spindle lubrication and also Lubrication of other precision machine parts and bearings

Advanced anti-wear, anti-oxidation, and anti-corrosion additives extend equipment life.

High viscosity index oils maintain lubricity and film strength across wide temperature ranges.

Suitable for a broad spectrum of hydraulic systems, spindles, CNC tools, and industrial gearboxes.

Lubeco | Pratap Tex-Chem Pvt. Ltd.

WhatsApp us

WhatsApp us