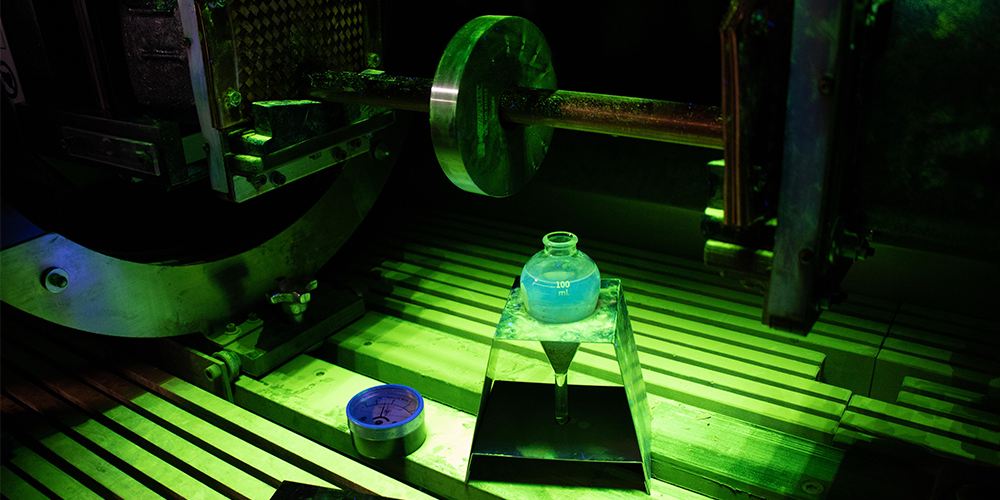

With a strong focus on operator safety, environmental compliance, and ease of use, Lubeco’s MPI products are trusted by automotive, aerospace, foundry, and heavy engineering sectors for both manual and automated testing systems. By delivering precision, reliability, and safety, we help manufacturers meet stringent quality control and industry standards.

Detects cracks, laps, and inclusions in critical automotive and aerospace components.

Provides high sensitivity for identifying porosity and structural flaws in powdered metal parts.

Reliable detection of surface discontinuities in foundry and general engineering applications.

Optimized for inspection after quenching, tempering, or case-hardening processes.

Compatible with other ferrous substrates commonly tested in magnetic particle inspection.

Lubeco | Pratap Tex-Chem Pvt. Ltd.

WhatsApp us

WhatsApp us