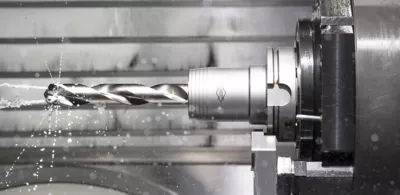

Hot rolled steel, cold rolled steel, cast iron, forged steel, mild steel, stainless steel.

Aluminium foils, aluminium fins, copper alloys, yellow metals, brass.

Precision forming and punching applications requiring high cleanliness and non-staining performance.

Aluminium foil, aluminium fins, CRC‑HRC steel sheets, yellow metals

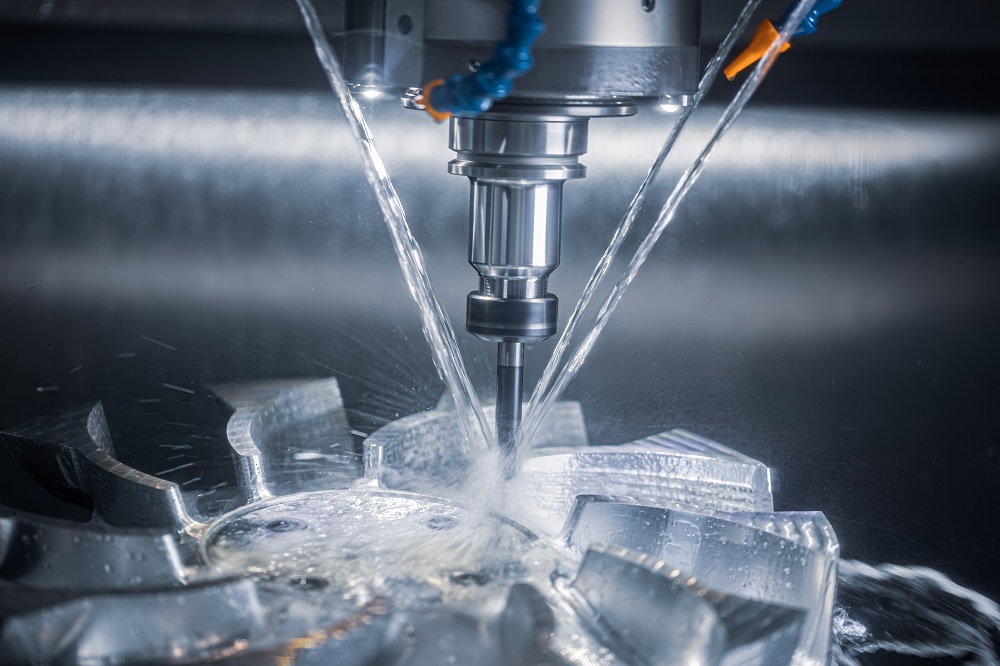

Cast iron, mild steel, forged steel, aluminium, copper, stainless steel

WhatsApp us

WhatsApp us