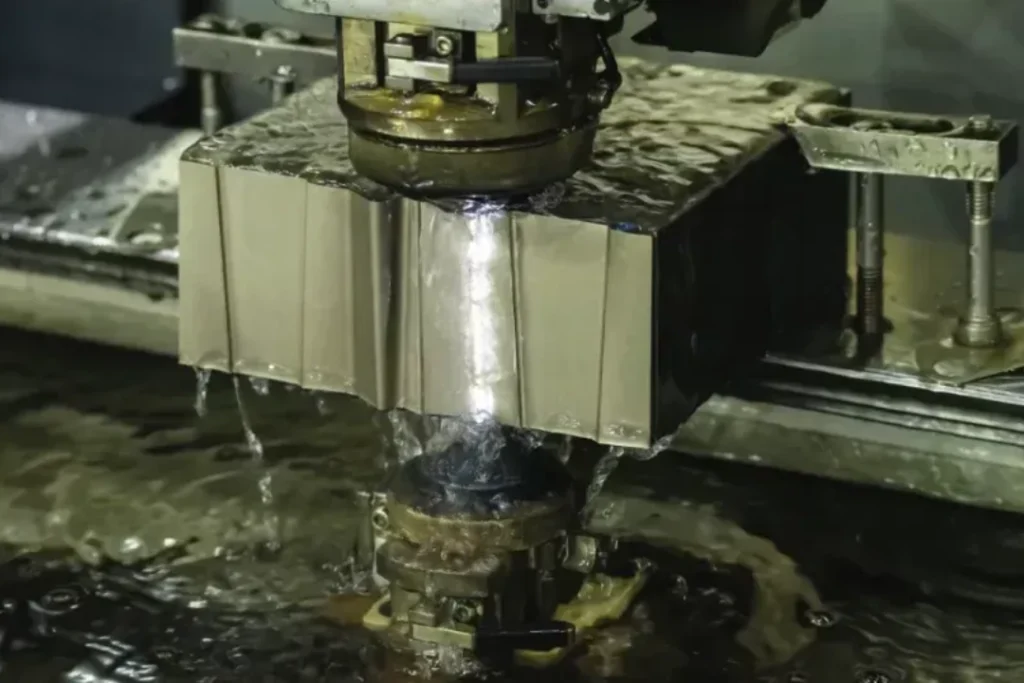

Lubeco’s EDM and wire EDM fluids are formulated for superior chip evacuation, stable spark gaps, and clean machining environments, supporting industries where accuracy, repeatability, and process reliability are critical, such as tool and die, automotive, aerospace, and precision engineering.

Ideal for cavity EDM and precision machining

Aluminium, copper, brass, yellow metals

Cast iron, mild steel, alloy steel, stainless steel

Graphite electrodes, copper electrodes, brass and molybdenum wire

Premium semi‑synthetic dielectric fluid with excellent oxidation stability, designed for high‑precision EDM, especially with graphite electrodes.

High‑performance, oil‑free, water‑soluble lubricant/coolant for reusable wire cut EDM, offering superior heat removal and debris flushing for extended precision cutting.

Lubeco | Pratap Tex-Chem Pvt. Ltd.

WhatsApp us

WhatsApp us