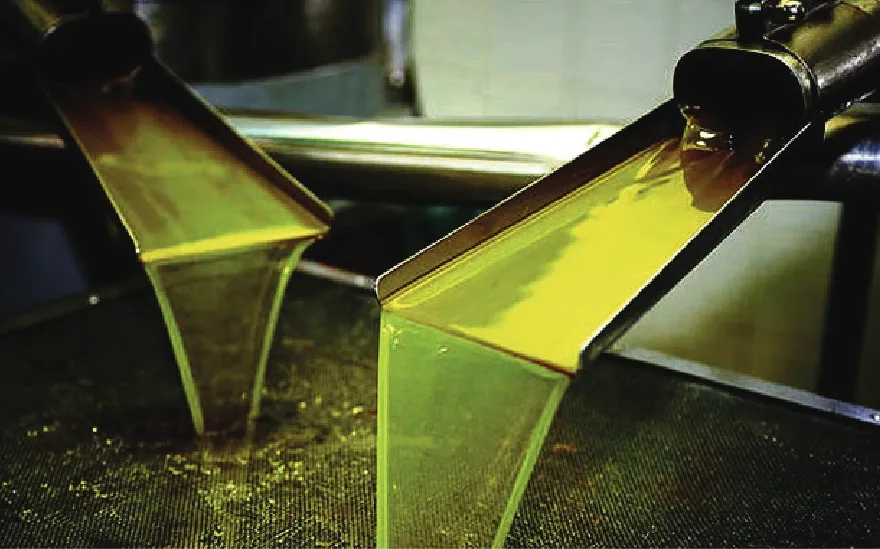

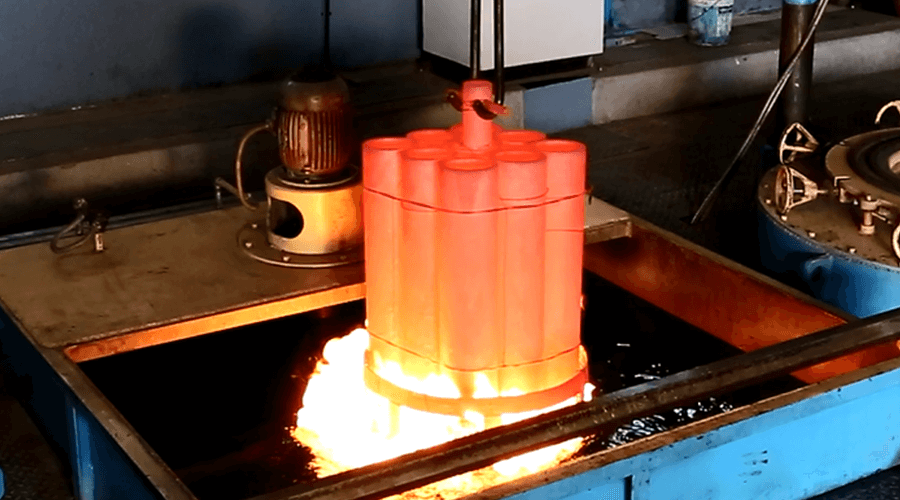

Quenching oils and polymer quenchants are specialized fluids used in heat treatment processes to control the rate of cooling in metals and alloys. Unlike water or brine solutions, these engineered fluids provide uniform, distortion-minimized quenching with reduced cracking risks, making them essential in hardening, induction, flame treatment, and precision manufacturing. Quenching oils are typically formulated with refined mineral, synthetic, or GTL base oils enhanced for high flash points, thermal stability, and oxidation resistance, ensuring safe and consistent cooling.

Polymer quenchants, on the other hand, are water-soluble organic polymers that deliver adjustable cooling rates, biostability, and excellent wetting properties, offering a cleaner and safer alternative to traditional salt or caustic solutions. Together, they provide critical process reliability across automotive, aerospace, tooling, and engineering industries.