Using water instead of water-soluble metal cutting fluid is not advised due to inadequate lubrication, cooling, and corrosion protection.

Using water instead of water-soluble metal cutting fluid may be possible in some situations, but it depends on the specific cutting process and materials involved. Water-soluble metal cutting fluids are designed to provide lubrication, cooling, and corrosion protection during machining operations. They are formulated to enhance the performance of cutting tools, improve surface finish, and extend tool life.

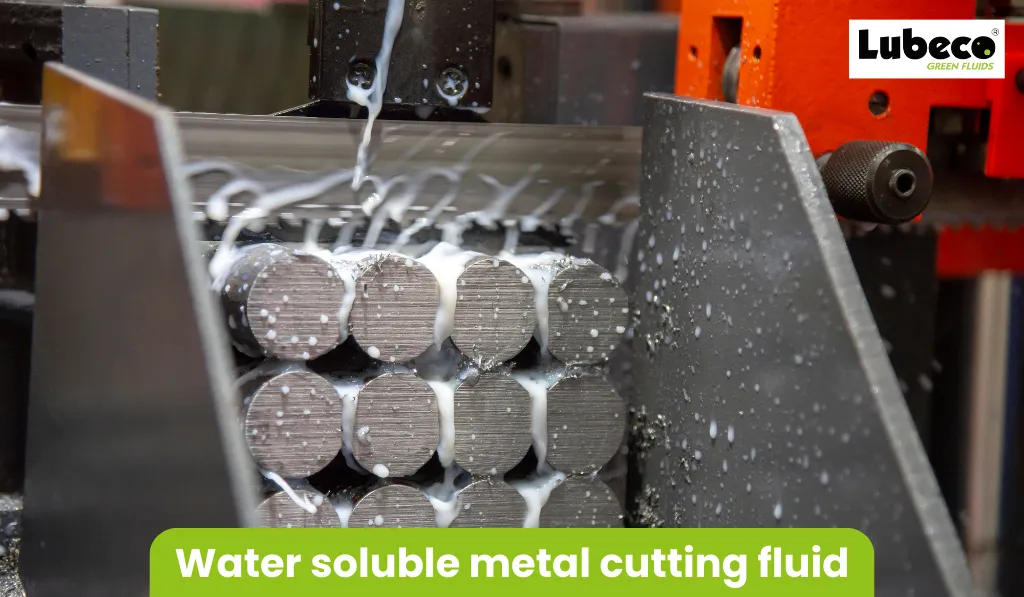

Overview of Water-Soluble Metal Cutting Fluids:

Water-soluble metal cutting fluids are like superheroes for machining! They have three main powers that make them super important:

- Lubrication: They work like a smooth operator, reducing friction between the cutting tool and the material. This means less wear and tear on the tool, making it last longer.

- Cooling: Just like a cooling breeze on a hot day, these fluids help dissipate the heat generated during cutting. This keeps everything from getting too hot and damaging the tool or the material.

- Corrosion Protection: They act like a shield, protecting metal surfaces from rust and other damage.

Potential Issues with Using Water Alone:

Using water alone in machining processes can lead to several potential issues:

- Limited Lubrication:

- Water lacks inherent lubricating properties, leading to increased friction between the cutting tool and the workpiece. This heightened friction can accelerate tool wear and reduce the overall lifespan of cutting tools, impacting their efficiency and performance.

- Corrosion Risk:

- Water, without corrosion inhibitors, exposes metal surfaces to the risk of rust and corrosion. This not only affects the longevity of cutting tools but can also compromise the quality of machined surfaces. Corrosion can lead to the degradation of metal components, impacting the overall integrity of the machining process.

- Inadequate Cooling:

- Water may not provide sufficient cooling during high-speed machining operations. Inefficient cooling can result in elevated temperatures, risking thermal damage to both the workpiece and the cutting tool. Proper cooling is essential to maintaining the structural integrity of the workpiece and ensuring the longevity of the tool.

- Poor Chip Evacuation:

- Efficient removal of chips is crucial for the smooth progression of the cutting process. Water alone may not facilitate effective chip evacuation, leading to chips accumulating in the machining area. Poor chip evacuation can interfere with the cutting process, affecting the overall efficiency and precision of machining operations.

- Microbial Growth:

- Water creates a conducive environment for microbial growth, posing contamination risks. Microbial contamination not only jeopardizes the quality of the machining process but can also lead to health concerns. The presence of microbes can compromise the cleanliness and safety of the machining environment.

- Material Compatibility Issues:

- Water may not be compatible with certain materials commonly used in machining. This limitation restricts the application of water as a cutting fluid to specific materials, limiting its versatility and effectiveness in diverse machining operations.

- Environmental Concerns:

- Disposal of water used in machining, especially when containing residues from the cutting process, may pose environmental challenges. Unlike specialized cutting fluids, water alone may lack features for environmentally responsible disposal, adding to the ecological impact of machining activities.

- Reduced Machining Precision:

- The cumulative impact of these limitations can result in less accurate cuts and reduced overall precision in the machining process. Precision is crucial in industries where tight tolerances and high-quality finishes are essential, highlighting the importance of using specialized cutting fluids to optimize machining outcomes.

In demanding machining operations, specialized cutting fluids are preferred to address these drawbacks and optimize performance.

Type of cutting fluid that cannot be mixed with Water –

Oil-based cutting fluids, also known as neat oils or straight oils, are a type of cutting fluid that cannot be mixed with water. Neat oils are composed of base oils, often mineral oils or synthetic oils, and do not contain water-soluble additives. Attempting to mix these oil-based cutting fluids with water can result in phase separation, reducing their effectiveness and potentially causing issues such as poor lubrication, corrosion, and microbial growth. Therefore, it’s important to use neat oils as intended, without diluting them with water.

Choosing the Right Metal Cutting Fluid for Your Application:

Choosing the right metal cutting fluid for your application is a critical decision that significantly influences machining performance and tool longevity. Here’s a comprehensive guide to help you make informed decisions tailored to your specific needs:

Material Compatibility: Select a fluid suitable for the metal being machined.

Consider the composition and properties of the metal you are machining. Different metals may require specific cutting fluids to ensure compatibility and optimal performance.

Cutting Operation: Choose based on the specific machining process.

Analyze the nature of your machining operation, whether it involves milling, turning, grinding, or other processes. Each operation has unique demands, and the cutting fluid should align with these requirements.

Cooling and Lubrication: Consider the fluid’s cooling capabilities for heat generated during high-speed operations.

Evaluate the cutting fluid’s ability to dissipate heat generated during high-speed machining. Effective cooling is essential to prevent thermal damage to the workpiece and cutting tools, while lubrication reduces friction and wear.

Environmental Impact: Opt for fluids that are environmentally friendly and pose minimal health risks.

Prioritize cutting fluids with formulations that are environmentally sustainable and have low health risks for operators. This ensures a responsible and safe working environment.

Tool and Machine Compatibility: Ensure compatibility with cutting tools and machinery.

Verify that the chosen cutting fluid is compatible with the materials used in cutting tools and machinery. Incompatibility can lead to performance issues and premature wear.

Corrosion Protection: Look for fluids with corrosion inhibitors based on workpiece and tool susceptibility.

Protect both the workpiece and cutting tools by selecting a cutting fluid with corrosion inhibitors. This is particularly important when working with metals prone to corrosion.

Maintenance Requirements: Consider ease of cleaning and overall maintenance.

Assess the ease of cleaning and general maintenance associated with the cutting fluid. Opt for fluids that streamline maintenance tasks, minimizing downtime.

Microbial Stability: Choose fluids resistant to microbial contamination if necessary.

In environments where microbial contamination is a concern, opt for cutting fluids with inherent resistance to microbial growth, maintaining a clean machining environment.

Regulatory Compliance: Ensure compliance with industry safety and environmental standards.

Confirm that the chosen cutting fluid complies with industry-specific safety and environmental standards, ensuring a secure and environmentally responsible approach to machining.

Cost Considerations: Compare upfront and long-term costs, considering tool life, waste disposal, and health risks.

Conduct a thorough cost analysis, weighing both initial and long-term expenses. Consider factors such as tool life, waste disposal methods, and potential health risks to make a financially informed decision while prioritizing efficiency and safety in machining operations.

Here is where you can learn more about applications for water-soluble cutting fluids.

This comprehensive evaluation ensures the chosen fluid aligns with specific application needs, promoting efficient machining and tool longevity. Regular monitoring is key to optimal performance.

Conclusion –

To sum it up, using water instead of the right metal cutting fluid can cause problems like friction, rust, and inadequate cooling during machining. While water might work in some situations, it’s not the best choice for precision and tool durability. Specialized cutting fluids are better for tough jobs. Also, it’s important not to mix water with certain oil-based fluids, as this can lead to issues like poor lubrication and rust. Picking the best cutting fluid involves considering things like what metal you’re working with, how you’re cutting it, and the impact on the environment and cost. Regularly checking and taking care of the fluid is key for it to keep working well over time.